Welcome to the Ender 3 Manual, your comprehensive guide to understanding and mastering the Creality Ender 3 3D printer. This manual covers setup, operation, and troubleshooting to ensure an optimal printing experience.

1.1 Overview of the Ender 3 Series

The Creality Ender 3 Series is a popular line of 3D printers known for affordability and performance. It features a compact, sturdy aluminum frame, a heated print bed, and a build volume of 220x220x250mm. The series supports FDM technology, enabling high-quality prints with various filaments. Designed for ease of use, the Ender 3 is partially assembled, making it accessible for beginners while offering advanced features for experienced users. Its versatility and reliability make it a favorite among hobbyists and professionals alike.

1.2 Importance of Reading the Manual

Reading the Ender 3 Manual is crucial for ensuring a safe and effective printing experience. It provides detailed instructions for assembly, calibration, and operation, helping users avoid common mistakes. The manual highlights safety precautions, such as proper voltage selection and handling of heated components. Even experienced users benefit from understanding specific features and troubleshooting tips. By following the guide, users can optimize print quality, prevent damage, and maximize the printer’s performance. It serves as an essential resource for both beginners and advanced users.

1.3 Safety Precautions

Adhering to safety guidelines is essential when operating the Ender 3. Always ensure proper voltage selection (230V or 115V) to match your local mains. Avoid using the printer in ways not described in the manual to prevent injury or damage. Keep children under 10 years old away from the printer unless supervised. Ensure good ventilation and avoid touching hot components like the extruder or heated bed. Regularly inspect wires and connections to prevent electrical hazards. Follow all instructions carefully to ensure safe and reliable operation.

Technical Specifications of the Ender 3

The Ender 3 features a build volume of 220x220x250mm, FDM technology, and compatibility with PLA, ABS, and PETG filaments. It supports a max print speed of 180mm/s, with a heated print bed reaching 110°C and an extruder up to 265°C. The printer includes a sturdy aluminum frame, resume print function, and compatibility with various slicing softwares, making it versatile for both beginners and experienced users.

2.1 Build Volume and Print Size

The Ender 3 offers a build volume of 220mm x 220mm x 250mm, providing ample space for creating various objects. The print bed measures 235mm x 235mm, slightly larger than the build volume, ensuring efficient printing. This dimension allows users to produce decent-sized prints, making it suitable for both hobbyists and professionals. The printer supports a wide range of filament types, enhancing its versatility for different projects.

2.2 Print Technology and Materials

The Ender 3 utilizes Fused Deposition Modeling (FDM) technology, extruding thermoplastic filaments layer by layer to create prints. It supports a variety of materials, including PLA, ABS, PETG, and even metal-filled or wood-filled filaments. The printer’s heated bed enables printing with materials that require higher temperatures. With proper calibration, the Ender 3 delivers high-quality prints, making it versatile for both casual and advanced projects. The layer resolution can be adjusted from 0.1mm to 0.3mm, ensuring detailed and durable outputs.

2.3 Key Features of the Ender 3

The Ender 3 stands out for its robust aluminum frame, ensuring stability during printing. It features a heated print bed for consistent adhesion and supports a build volume of 220x220x250mm. The printer includes a resume printing function, preventing losses due to power outages. An optional touchscreen interface enhances user experience, while compatibility with various slicing software offers flexibility. Its open-frame design allows easy access and monitoring. These features make the Ender 3 a versatile and user-friendly option for both beginners and enthusiasts, delivering reliable results across various projects.

Assembly Guide

The Ender 3 assembly involves unboxing, inventorying parts, and following step-by-step instructions. Prepare tools, align frames, and secure components like the Z-axis and print bed. Tighten all connections properly for stability.

3.1 Unboxing and Inventory of Parts

Begin by carefully unboxing your Ender 3 printer to ensure all components are included. Check for the aluminum frame, print bed, extruder, motors, belts, and hardware like M5 screws and T-nuts. Verify the presence of tools such as Allen keys and wrenches. Cross-reference the parts list in the manual to confirm everything is accounted for. Organize the components neatly to streamline the assembly process. Missing or damaged parts should be reported to the supplier immediately to avoid delays.

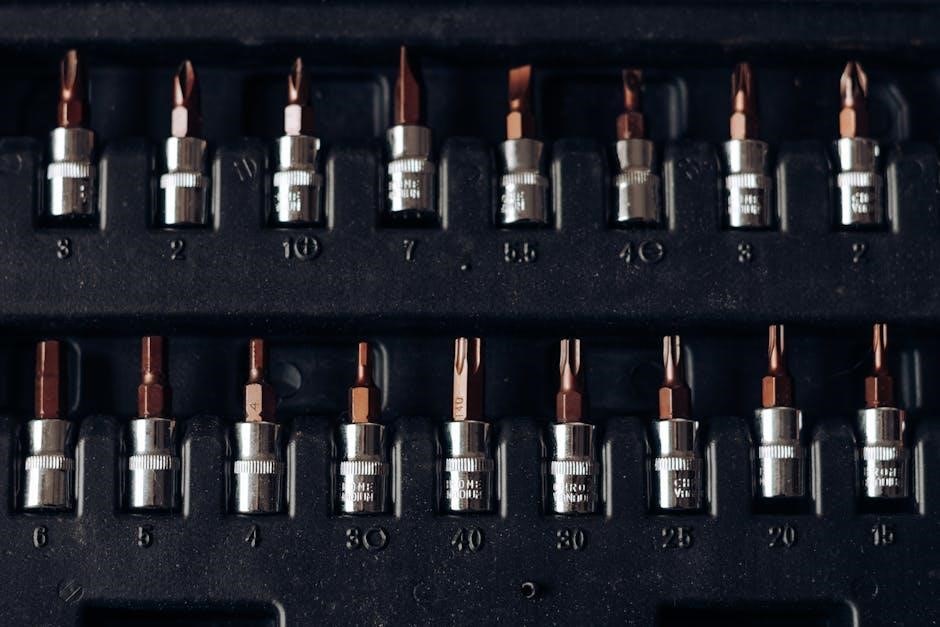

3.2 Preparing Tools and Workspace

To ensure a smooth assembly process, gather all necessary tools, including Allen keys, screwdrivers, wrenches, and pliers. Clear a large, sturdy workspace with good lighting to accommodate the printer’s frame. Cover the surface with cardboard or a work mat to protect it from scratches or debris. Organize small parts like screws and nuts in labeled containers to avoid misplacement. Ensure all components are within easy reach to streamline assembly. Refer to the manual for specific tool requirements and workspace recommendations.

3.3 Step-by-Step Assembly Instructions

Begin by carefully unpacking and organizing all components. Follow the manual’s visual guides to align the frame and attach the print bed using M5 screws and T-nuts. Secure the Z-axis gantry to the frame, ensuring proper alignment. Install the extruder and hotend, connecting them to the X-axis carriage. Use the provided Allen key to tighten all connections firmly. Attach the electronics box and connect wires according to the wiring diagram. Finally, mount the filament holder and perform a visual inspection to ensure all parts are correctly assembled.

3.4 Installing the Print Bed and Z-Axis

Install the print bed by attaching it to the Z-axis gantry using M5 screws and T-nuts. Ensure proper alignment with the gantry’s mounting slots. Tighten all screws evenly to maintain stability. Next, mount the Z-axis gantry to the printer’s frame using M5x45 screws, ensuring it is level and securely fastened. Finally, connect the Z-axis motor to the motherboard, following the wiring diagram provided. Double-check all connections for tightness and proper alignment to ensure smooth operation during printing.

3.5 Connecting Wires and Electronics

Begin by connecting the Z-axis motor to the motherboard, ensuring the wires match the correct ports. Next, connect the extruder motor and hotend wires, following the wiring diagram provided in the manual. Carefully attach the power supply to the motherboard, ensuring all connections are secure. Finally, connect the bed leveling springs and any additional sensors, such as the filament runout sensor. Double-check all connections for tightness and proper routing to prevent electrical interference or damage. Power on the printer and test each component to ensure functionality.

First-Time Setup

Configure your Ender 3 by selecting the correct voltage, installing firmware, and leveling the bed. Load filament and ensure all components are properly connected for a smooth first print experience.

4.1 Power Supply and Voltage Selection

Before powering up your Ender 3, ensure the power supply is set to the correct voltage (230V or 115V) to match your local mains. Locate the voltage switch on the power supply unit and adjust it accordingly. Incorrect voltage selection can damage the printer or pose safety risks. Always double-check your local power requirements to avoid electrical issues. This step is crucial for safe and reliable operation of your 3D printer.

4.2 Firmware Installation and Configuration

Installing and configuring the correct firmware is essential for optimal performance of your Ender 3. Download the latest firmware from Creality’s official website or the provided TF card. Use a compatible slicing software to upload the firmware to your printer. Ensure the firmware matches your printer model and hardware configuration. Incorrect firmware can lead to malfunctions. After installation, configure settings like print speed, temperature, and axis limits to suit your preferences. This step ensures smooth operation and unlocks advanced features like resume printing and touch screen support.

4.3 Bed Leveling Process

The bed leveling process ensures your Ender 3 print bed is properly aligned for consistent printing. Use the control knob to move the nozzle to each corner and the center of the bed. Tighten or loosen the spring-loaded screws at each corner to adjust the bed height. Ensure the nozzle is just touching the bed without applying too much pressure. Proper leveling is crucial for preventing print adhesion issues and achieving high-quality prints. Regularly check and adjust the bed level, especially after transporting or modifying the printer.

4.4 Loading Filament

Loading filament into your Ender 3 is a straightforward process. Preheat the extruder to the recommended temperature for your filament type. Cut the filament at a 45-degree angle for easier feeding. Access the “Preheat” and “Filament” options in the menu to prepare the extruder. Insert the filament into the extruder feeder, ensuring it seats properly. The printer will pull the filament through automatically. Once loaded, the printer is ready to resume printing. Always handle hot components with care and verify the filament is securely loaded to avoid jams or issues during printing.

First Print Guide

Welcome to your first print with the Ender 3! This guide will walk you through preparing your print file, setting up slicing software, and starting your first print successfully.

5.1 Preparing the Print File

Preparing the print file is the first step in your printing journey. Start by obtaining a 3D model in STL format from trusted sources. Use slicing software like Cura or Slic3r to convert the STL into G-code. Ensure the printer profile is set to “Creality Ender 3” and adjust settings like layer height, infill density, and support material as needed. Save the G-code file to an SD card or transfer it via USB. Proper file preparation ensures smooth printing and high-quality results.

- Use STL files for 3D models.

- Configure slicing settings for optimal prints.

- Save G-code to an SD card or USB.

5.2 Slicing Software Setup

Setting up slicing software is crucial for preparing your 3D model for printing. Popular tools like Cura and Slic3r allow you to convert STL files into G-code. Start by selecting the Creality Ender 3 printer profile to ensure compatibility. Adjust settings such as layer height, infill density, and support material based on your print requirements. These settings optimize print quality and material usage. Once configured, export the G-code file, which the printer will use to execute the print job accurately.

- Select the Ender 3 printer profile.

- Adjust layer height and infill settings.

- Export G-code for printing.

5.3 Starting Your First Print

Starting your first print with the Ender 3 is an exciting milestone. Ensure the print bed is leveled and the filament is loaded correctly. Transfer the G-code file to the printer via SD card or USB. Power on the printer, navigate to the print menu, and select your file. Confirm the settings and start the print job. Monitor the initial layers to ensure proper adhesion and adjust settings if necessary. Let the printer run its course, and enjoy the results of your first successful print!

- Load the G-code file to the printer.

- Start the print job from the menu.

- Monitor the first few layers closely.

5.4 Monitoring the Printing Process

Monitoring the printing process is crucial for ensuring high-quality results. Keep an eye on the nozzle height, as improper leveling can lead to adhesion issues. Ensure the filament flows smoothly and check for any blockages. Listen for unusual noises that may indicate mechanical problems. Maintain a safe distance and avoid touching moving parts. Regularly inspect the print bed to ensure proper adhesion and adjust settings if necessary. Proper monitoring helps prevent failures and ensures a successful print.

- Check nozzle height and bed adhesion.

- Ensure smooth filament flow.

- Monitor for unusual noises.

- Inspect the print bed regularly.

Calibration and Maintenance

Regular calibration and maintenance ensure optimal performance and longevity of your Ender 3. Adjust belt tensions, clean moving parts, and lubricate axes for smooth operation.

- Calibrate the extruder for accurate filament flow.

- Clean and lubricate the X, Y, and Z axes.

- Check and tighten all belts and screws.

6.1 Calibrating the Extruder

Calibrating the extruder ensures precise filament flow, crucial for consistent print quality. Start by heating the nozzle to the recommended temperature for your filament. Use the control knob to manually extrude filament, observing the flow. Adjust the extruder gear tension and idler lever to eliminate slippage or binding. Perform a calibration print or test extrusion to verify accuracy. Proper calibration prevents under or over extrusion, ensuring smooth layer adhesion and detailed prints.

- Heat the nozzle to the filament’s melting point.

- Use the control knob to test extrusion flow.

- Adjust the extruder gear and idler lever for smooth operation.

6.2 Adjusting Belt Tensions

Proper belt tension is essential for smooth operation and accurate prints. Begin by loosening the belt tensioners slightly. Tighten each belt evenly until it feels taut but not overly rigid. Use an Allen wrench to adjust the tensioning screws. Check tension by plucking the belt gently; it should produce a clear, resonant sound. Overly loose belts may cause layer shifting, while excessive tension can damage pulleys or motors. Regularly inspect and adjust belts to maintain optimal printing performance.

- Loosen tensioners slightly before adjusting.

- Tighten belts evenly for consistent tension.

- Check tension with a guitar tuner or by feel.

6.3 Cleaning and Lubricating Moving Parts

Regular cleaning and lubrication of moving parts ensure smooth operation and prevent wear. Use compressed air to remove dust from rails, pulleys, and belts. Apply a silicone-based lubricant to the X, Y, and Z axes’ linear rails and lead screws. Avoid over-lubrication to prevent attracting dust. Lubricate the pulleys and idlers sparingly. Clean and grease the extruder gears and hinges periodically. This maintenance routine enhances print quality and extends the printer’s lifespan.

- Clean rails and pulleys with compressed air.

- Apply silicone-based lubricant to linear rails and lead screws.

- Lubricate extruder gears and hinges as needed.

Troubleshooting Common Issues

This section addresses common issues like uneven layers, clogged extruders, poor bed adhesion, and firmware errors. Follow detailed solutions to resolve these problems effectively.

- Adjust bed leveling for even layers.

- Clear clogs in the extruder.

- Ensure proper adhesion settings.

- Update or reinstall firmware if glitching.

7.1 Bed Leveling Problems

Bed leveling issues are common in the Ender 3. If the print bed is uneven, prints may not adhere properly or the nozzle may drag, causing damage. To resolve this, ensure the springs are tightened evenly and adjust the bed screws methodically. Use the control knob to move the nozzle to each corner and center, adjusting until the paper test confirms proper leveling. If issues persist, check for worn springs or faulty sensors and replace them as needed to restore accurate bed leveling.

7.2 Filament Feeding Issues

Filament feeding problems can prevent the Ender 3 from printing correctly. Common issues include clogged extruders, insufficient tension on the filament, or incorrect extruder settings. To resolve this, ensure the PTFE tubing is clear and the filament path is unobstructed. Adjust the extruder tension by tightening or loosening the spring-loaded lever. If the issue persists, check for worn or damaged parts like the extruder gear or PTFE tube and replace them. Proper filament loading and ensuring the correct temperature settings can also prevent feeding issues.

7.3 Print Quality Issues

Print quality issues with the Ender 3 can arise from incorrect bed leveling, improper nozzle height, or uneven extrusion. To address this, ensure the print bed is leveled and the nozzle is at the correct height. Check for blocked extruders or worn-out nozzles, and clean or replace them as needed. Adjusting the temperature settings for the nozzle and bed can also improve print quality. Additionally, verify that the filament is feeding smoothly and that the belts are properly tensioned to avoid layer shifting or misalignment during printing.

7.4 Electronic and Firmware Glitches

Electronic and firmware issues can disrupt your printing experience. Common problems include the touchscreen freezing, motor malfunctions, or unexpected disconnections. To resolve these, restart the printer and ensure all connections are secure. Firmware bugs can cause erratic behavior, so updating to the latest version is essential. If issues persist, check for loose wires or corrupted firmware installations. In severe cases, reinstalling the firmware or using a bootloader may be necessary to restore proper functionality and ensure smooth operation of your Ender 3 printer.

Advanced Printing Techniques

Explore advanced techniques like adjusting print speed, temperature, and material settings for optimal results. Experiment with dual extruders, multi-material prints, and custom profiles to enhance creativity and precision in your projects.

8.1 Adjusting Print Speed and Temperature

Adjusting print speed and temperature is crucial for optimizing print quality and material compatibility. Print speed can be increased for faster results but may compromise detail. Reducing speed enhances precision. Temperature control ensures proper filament extrusion; higher temps suit materials like ABS, while lower temps are ideal for PLA. Monitor and fine-tune these settings in your slicer software or printer interface. Start with standard settings for your filament type, then adjust in small increments. Avoid extreme changes to prevent warping or adhesion issues. Proper calibration ensures consistent results and extends printer lifespan.

8.2 Using Different Filament Types

Explore various filament options to expand your printing capabilities. PLA is ideal for beginners, offering easy use and minimal warping. ABS is stronger but requires a heated bed. PETG combines durability with flexibility. Experiment with materials like Nylon for strength or TPU for flexibility. Adjust temperature, speed, and bed adhesion settings for optimal results. Higher temps suit ABS, while lower temps work best for PLA. Always follow filament-specific guidelines to ensure compatibility and achieve high-quality prints. Proper settings prevent issues like stringing or layer delamination.

8.3 Multi-Material Printing

Multi-material printing allows you to create complex designs with varied colors and properties. The Ender 3 can achieve this with upgrades like dual extruders or multi-material units. Ensure compatibility with your printer model and filament types. Calibrate extruder settings to prevent oozing or stringing. Use slicing software to assign different materials to specific parts of your model. This technique enhances creativity but requires precise adjustments. Experiment with combinations like PLA and TPU for rigid and flexible sections. Proper setup and calibration are key to achieving successful multi-material prints.

Upgrades and Enhancements

Enhance your Ender 3’s functionality with upgrades like dual extruders, direct drive systems, or silent motherboards. These improvements boost performance, versatility, and printing efficiency for advanced projects.

9.1 Recommended Upgrades for Ender 3

Enhance your Ender 3’s performance with popular upgrades. A direct drive extruder improves flexible filament handling, while a silent motherboard reduces noise. Upgrading to a dual Z-axis ensures smoother layer shifts and better stability. Installing a glass bed or PEI sheet enhances adhesion for various filaments. Consider adding auto bed leveling for effortless calibration. For advanced users, cooling upgrades like a dual-fan setup or an aftermarket hotend can significantly improve print quality and versatility.

9.2 Installing Upgrades

Installing upgrades on your Ender 3 can significantly enhance its performance. Always power off and unplug the printer before starting. Begin by disconnecting wires and removing screws to access the components. For a direct drive extruder, carefully remove the stock extruder and install the new unit, ensuring proper alignment. When upgrading the print bed, apply a thin layer of adhesive and align it precisely. Follow manufacturer instructions for motherboard or hotend replacements to avoid damage. Test each upgrade post-installation to ensure functionality and reliability.

9.4 Custom Modifications

Custom modifications allow you to tailor your Ender 3 to specific needs. Start with small tweaks, like adding belt tensioners for smoother axis movement or installing a touchscreen for easier operation. For advanced users, consider frame reinforcements or LED lighting for better print visibility. Always research and ensure modifications won’t void your warranty. Test each modification thoroughly to avoid affecting print quality. The Ender 3 community offers endless inspiration and guides for unique upgrades, making your printer truly one-of-a-kind.

Warranty and Support

The Ender 3 is backed by a limited warranty covering manufacturing defects for a specified period. For inquiries, contact Creality’s support team or visit their official website for assistance and resources.

10.1 Understanding the Warranty

The Creality Ender 3 is covered by a limited warranty that protects against manufacturing defects for a specified period, typically one year from the date of purchase. This warranty ensures that defective parts or issues arising from poor workmanship will be addressed by the manufacturer. To claim warranty benefits, users must register their product and provide proof of purchase. The warranty does not cover damage caused by misuse, unauthorized modifications, or normal wear and tear.

For warranty-related inquiries, contact Creality’s customer support team directly through their official website or support channels. Retaining the original purchase receipt is essential for warranty validation.

10.2 Contacting Customer Support

For any inquiries or issues with your Creality Ender 3, contact the Creality customer support team through their official website. Use the online contact form or email address provided for technical assistance, warranty claims, or general questions. Ensure to include your printer’s serial number and purchase receipt for faster processing. Additionally, Creality offers live chat support on their website for immediate help. Responses are typically provided within 24-48 hours, depending on the volume of inquiries. Visit Creality’s official website for detailed support options.

Official Resources

Access official Creality Ender 3 resources through their website, including detailed manuals, firmware updates, and community forums. Visit Creality.com for comprehensive support and downloads.

11.1 Downloading the Official Manual

The official Ender 3 manual is available for download from Creality’s website or the provided TF card. It includes detailed instructions for setup, calibration, and troubleshooting. Ensure you select the correct model (Ender 3, Ender 3 Pro, or Ender 3 V3) to download the appropriate version. The manual is provided in PDF format and covers essential topics like assembly, bed leveling, and firmware updates. Visit the Creality official website to access the latest version of the manual tailored to your specific printer model.

11.2 Creality Official Website

The Creality official website is a comprehensive resource for Ender 3 users. It offers detailed product information, firmware updates, and user guides specific to your printer model. Additionally, the site provides access to FAQs, troubleshooting tips, and a community forum where users can share experiences and solutions. Regularly visit the site for updates, as Creality frequently releases new software and hardware improvements to enhance your printing experience.

11.3 Community Forums and Groups

The Ender 3 community forums and groups are invaluable resources for users seeking advice, troubleshooting, or sharing experiences. Platforms like Facebook groups, Reddit communities, and specialized forums host active discussions. These spaces allow users to connect, learn from experts, and showcase their projects. Whether you’re a beginner or an advanced user, these communities provide a wealth of knowledge and support to enhance your 3D printing journey with the Ender 3.